Comparison of Ca(NO3)2 and CaCl2 Admixtures on Reaction, Setting, and Strength Evolutions in Plain and Blended Cementing Formulations

Abstract

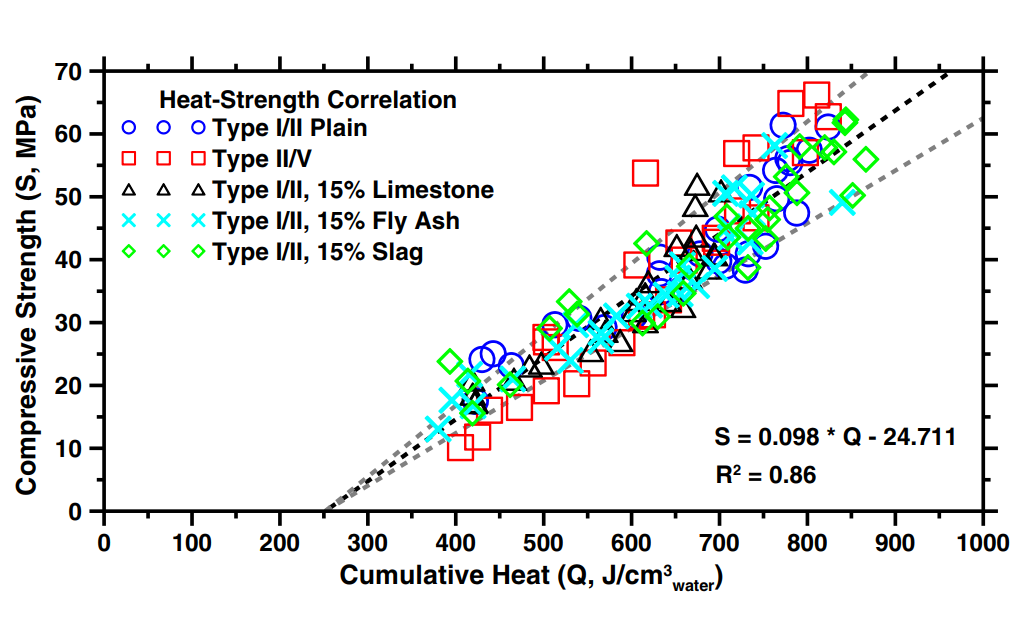

Due to the role of Cl− ions in inducing the corrosion of steel rebar in reinforced concrete, it is of interest to use chloride-free accelerators in concrete construction. Ca(NO3)2 (CN) is a Cl− free admixture, which accelerates set and is thought to inhibit steel corrosion. This study carefully compares the influences of both Ca(NO3)2 and CaCl2 (CC) additions on reaction and property evolutions across a range of cementing materials including ordinary portland cements (OPCs) and blended OPCs, i.e., those containing Class F fly ash, slag, or fine limestone. The results indicate that CN acts as a set accelerator, though in relation to its dosage a slight drop in early age (i.e., 1 day) strength is noted. However, this effect is transient, with similar strengths being recorded across all dosage levels by 28 days. While CC is noted to be a superior (i.e., setting and hardening) accelerator, both additives show similar performances by 28 days. The results from a phase boundary nucleation and growth (BNG) model indicate that differences in admixture performance are a function of the differing abilities of these admixtures (and specifically, their anions) to accelerate chemical reactions. Based on observed behaviors, recommendations are made for dosing both admixtures as a function of the binder chemistry. While the benefits of these additives vary as a function of the OPC chemistry, the results indicate that CN, on account of its Cl−free composition, is a very promising accelerator for use in concrete construction.