Puerta-Falla, G.; Kumar, A.; Gomez-Zamorano, L.; Bauchy, M.; Neithalath, N.; Sant, G. Construction and Building Materials 2015, 96, 657-665.

The influence of filler type and surface area on the hydration rates of calcium aluminate cement

Abstract

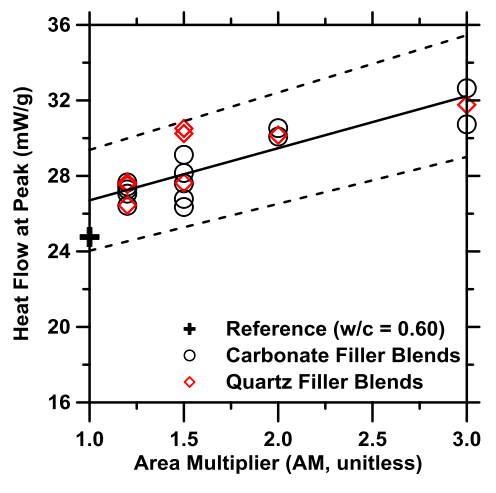

The addition of finely pulverized materials such as limestone and quartz has been observed to increase the reaction rates of ordinary portland cement. This study describes the effects of mineral fillers including: limestone, dolomite and quartz on the hydration rates of calcium aluminate cements. By detailed analysis of isothermal calorimetry data and application of a phase boundary nucleation and growth model, it is shown that finely ground minerals enhance reaction rates in relation to: (1) their surface area, which increases with increasing proportion of CAC replacement by a fine mineral filler, and (2) the increase in the amount of water available for CAC hydration, i.e., dilution, that occurs as the CAC is replaced by a filler. Unlike in the case of OPC, CAC hydration rates, and enhancements therein in the presence of fillers are independent of the mineral type and are only a function of available surface area.